Each transactions performed using warehouse is stored in a Warehouse Register.

For each transaction or movement in the warehouse is recorded in Warehouse Entry table.

Warehouse Documents and Warehouse Journal are used to register item movements in the warehouse.

Whenever an item in the warehouse is moved, received, put away, picked, shipped, or adjusted, Warehouse Entries are registered to store the physical information about zone, bin, and quantity

The Bin Content table is used to handle all the different dimensions of the contents of a bin per item, such as unit of measure, maximum quantity, and minimum quantity.

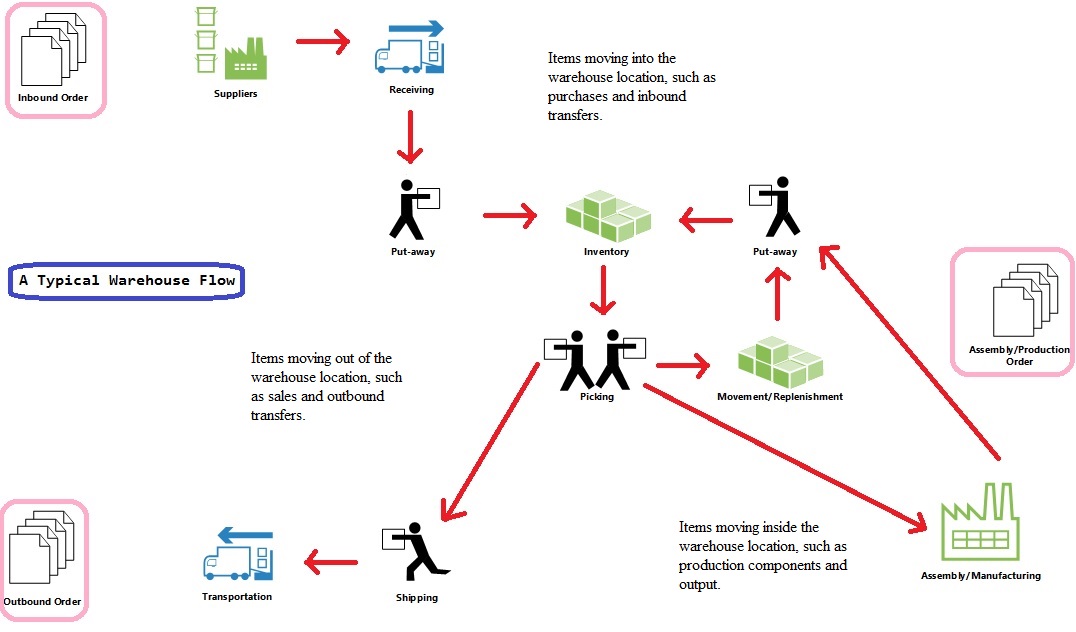

Below is the typical Warehouse Flow:

Basic UI Documents

- Inventory Put-away

- Inventory Pick

- Inventory Movement

- Item Journal

- Item Reclassification Journal

Advanced UI Documents

- Warehouse Receipt

- Put-away Worksheet

- Warehouse Put-away

- Pick Worksheet

- Warehouse Pick

- Movement Worksheet

- Warehouse Movement

- Internal Whse. Pick

- Internal Whse. Put-away

- Bin Creation Worksheet

- Bin Content Creation Worksheet

- Whse. Item Journal

- Whse. Item Reclass. Journal

Below are the warehouse-related granules in Navision:

- Basic Inventory (4010)

- Bin (4170)

- Put Away (4180)

- Warehouse Receipt (4190)

- Pick (4200)

- Warehouse Shipment (4210)

- Warehouse Management Systems (4620)

- Internal Picks and Put-aways (4630)

- Automated Data Capture System (4640)

- Bin Setup (4660)

Granules Vs UI Documents:

The following table shows which granules are required to define different warehouse complexity levels, which UI documents support each level.

| Complexity level | Description | UI document | Minimum granule requirement |

| 1 | No dedicated warehouse activity. Receive/ship posting from orders. | Order | Basic Inventory |

| 2 | No dedicated warehouse activity. Receive/ship posting from orders. Bin code is required. | Order, with bin code | Basic Inventory/Bin |

| 3 | Basic warehouse activity, order-by-order. Receive/ship posting from inventory put-away/pick documents. Bin code is required. | Inventory Put-away/Inventory Movement/Inventory Pick, with bin code | Basic Inventory/Bin/ Put Away/Pick |

| 4 | Advanced warehouse activity, for multiple orders. Consolidated receive/ship posting based on warehouse put-away/pick registrations. | Warehouse Receipt/Warehouse Put-away/Warehouse Pick/Warehouse Shipment/Pick Worksheet | Basic Inventory/ Warehouse Receipt/ Put Away/ Pick/ Warehouse Shipment |

| 5 | Advanced warehouse activity, for multiple orders. Consolidated receive/ship posting based on warehouse put-away/pick registrations. Bin code is required. | Warehouse Receipt/Warehouse Put-away/Warehouse Pick/Warehouse Shipment/Pick Worksheet/Put-away Worksheet, with bin code | Basic Inventory/Bin/ Warehouse Receipt/ Put Away/Pick/ Warehouse Shipment |

| 6 This level is referred to as “WMS”, since it requires the most advanced granule, Warehouse Management Systems. | Advanced warehouse activity, for multiple orders. Consolidated receive/ship posting based on warehouse put-away/pick registrations. Bin code is required. Zone/class code is optional. Warehouse workers directed by workflow. Bin replenishment planning. Bin ranking. Bin setup by capacity. Slotting. Hand-help device integration. | Warehouse Receipt/Warehouse Put-away/Warehouse Pick/Warehouse Shipment/Warehouse Movement/Pick Worksheet/Put-away Worksheet/Internal Whse. Pick/Internal Warehouse Put-away, with bin/class/zone code Various worksheets for bin management ADCS screens | Basic Inventory/Bin/ Put Away/ Warehouse Receipt/ Pick/ Warehouse Shipment/ Warehouse Management Systems/ Internal Picks and Put-aways/ Bin Setup/ Automated Date Capture System/ Bin Setup |

I will come up with more details in my next post.

[…] Bron : Ashwini Tripathi Lees meer… […]

ReplyDelete